Originally Published by Design World

By Jeff Shepard | February 3, 2023

Rotary slip ring connectors are important components in various applications like multi-axis robots in industry 4.0, wind turbines for sustainable green energy, machine tools, medical systems, and more.

This FAQ considers how slip ring connectors differ from commutators, and looks at how mercury-wetted, pancake, and wireless slip ring connectors work. Their capabilities and reviews applications where they are used to transfer power, control circuits, transmit analog or digital signals, or liquids and gases.

Slip rings, split rings, and commutators

Slip rings and split rings are both designed to maintain electric circuit continuity between fixed and rotary sections in a mechanical system. The difference is that a slip ring can transmit signals and or power between the sections, while a split ring is used to reverse the direction of current flow as the rotary section spins.

A split ring is literally split into at least two pieces; in some designs, there are multiple splits in the ring. When split into two and used in a commutator, the split ring is alternately connected to the poles of a motor, reversing polarity as the motor spins. The split ring is connected to the motor poles with brushes. The combination of the split ring and brushes is called a commutator.

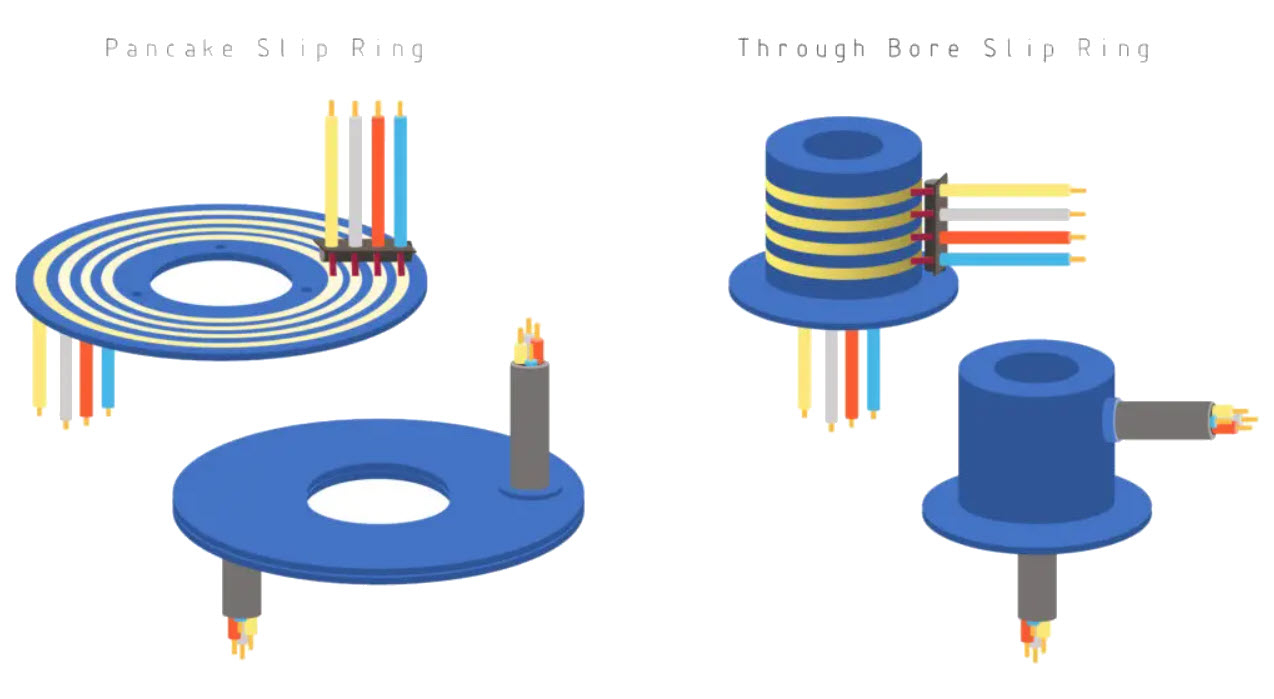

Slip rings are also called rotary joints, rotary electrical interfaces, rotating connectors, collectors, and swivels. They are available in various geometries and constructions, like a pancake and through bore designs (Figure 1).

Slip ring construction

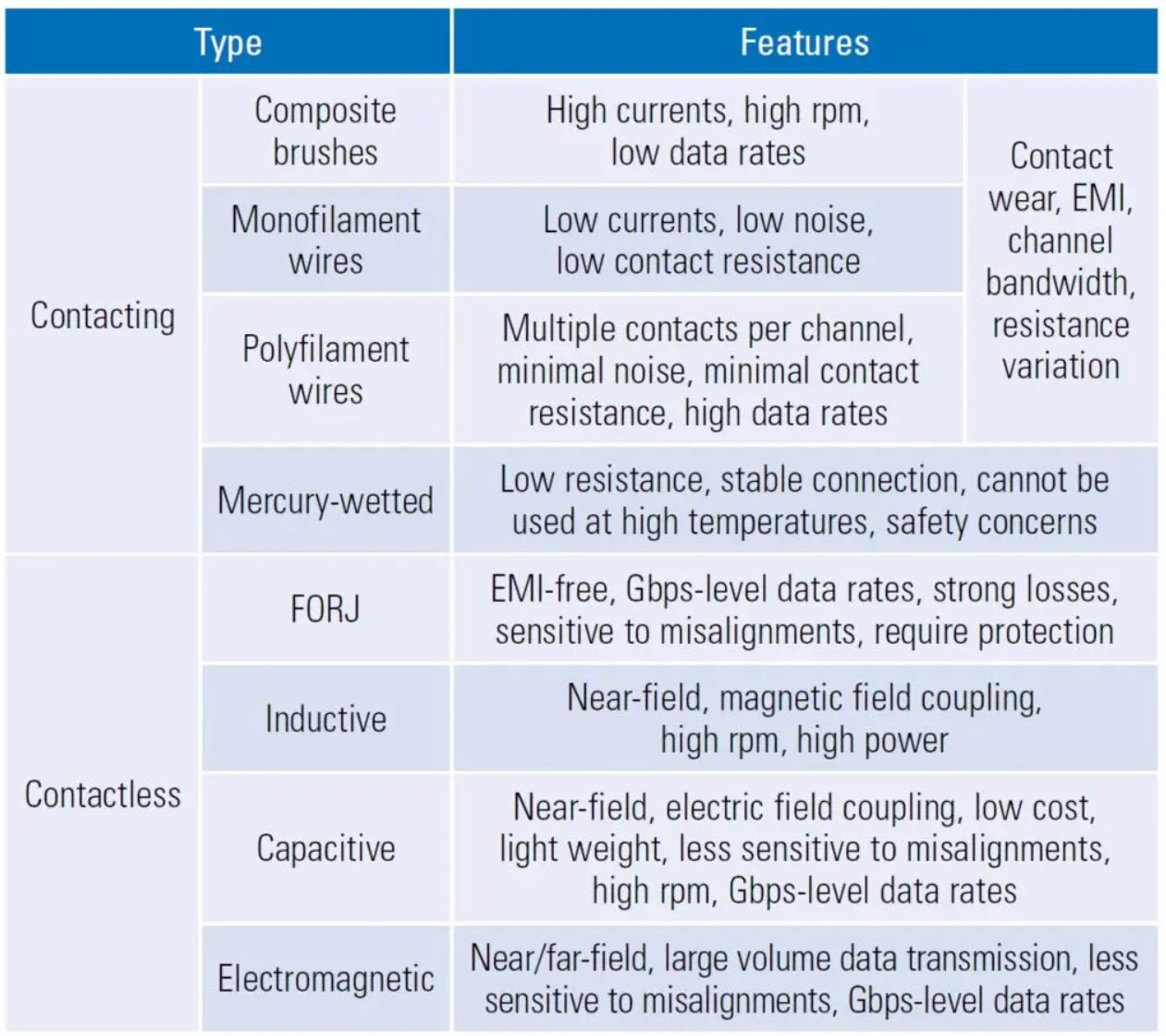

The most common slip ring constructions are based on mechanical connections, with brushes on a stator that slide against conducting rings on a rotor. The brushes can be made from various conductive materials, and the selection of material is based on several factors, including signal bandwidth, the amount of power to be transmitted, quality of the signal or power to be transmitted, speed of rotation, environmental factors, and reliability requirements. The moving mechanical contacts often require monitoring and frequent maintenance. Environmental factors are often the most limiting factor in the performance of mechanical slip rings. In addition, the sliding contacts can generate vibrations and electrical noise that can reduce the quality of the transmitted signals. That can be especially troublesome in applications requiring real-time control, like robotics. Several other slip ring designs are available to meet the demands of specific applications.

Mercury-wetted slip rings

Mercury-wetted slip rings replace the sliding brush contacts with a pool of liquid mercury bonded to the contacts. The mercury maintains a low friction and efficient electrical connection between the two sides of the slip ring. Mercury solidifies at about -40 °C, which can limit the use of this design. In addition, mercury is a toxic substance and poses safety challenges.

Wireless slip rings

Wireless slip rings transmit signals and power using magnetic coils on either side of the slip ring and produce contactless and frictionless transfers. These designs are more suited for harsh environments, requiring less maintenance than conventional moving mechanical contacts. Wireless slip rings can transmit higher frequency signals with higher quality and less interference, but they are limited in the amount of power they can transmit. If power coupling is important, a traditional moving contact slip ring can usually transmit several orders of magnitude more power in the same size solution.

Fiber optic slip rings

Fiber optic rotary joint (FORJ) is a type of contactless slip ring designed for data transmission only. FORJs are particularly useful in high EMI environments and typically use 850 or 1550 nm infrared transmission of analog or digital signals and can data rates of 50 Gbps or higher. FORJs can be challenging to implement and suffer from high signal attenuation if not precisely aligned in angular and axial directions. Misalignments can also result in rotational signal fluctuations. Because of their sensitivity, using FORJs in industrial environments can be especially challenging and demand high levels of protection, increasing installed costs.

Inductive and capacitive slip rings

Near-field coupling using electric or magnetic fields can also implement non-contact slip rings. In these designs, non-radiating capacitive and inductive circuit elements transmit data or power.

Capacitive slip rings use electric fields to transmit data. These solutions are robust, low-cost, and lightweight. They also have excellent performance even when misaligned and can support data transmission speeds of several Gbps in harsh environments independent of rotational speed. Because of their robust and high-speed performance, capacitive slip rings are used in time-sensitive industrial applications like robotics and are complimentary with the Ethernet fieldbuses.

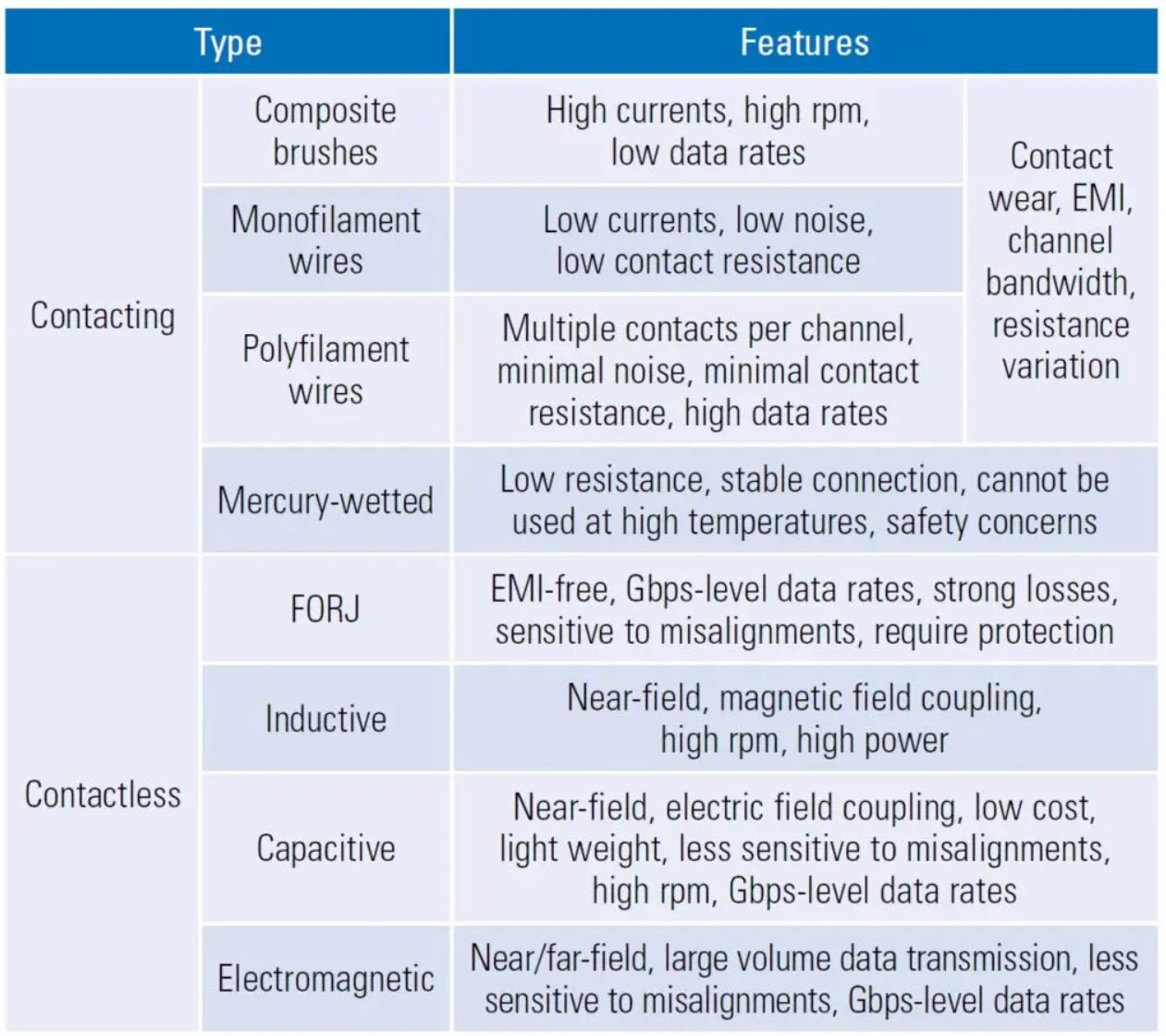

Inductive slip rings use electromagnetic induction and are suited to different applications. Like capacitive slip rings, inductive designs are suited for industrial applications with high rotation speeds. In contrast with capacitive slip rings, inductive slip rings are better suited for power transmission rather than data transmission. The blade pitch control systems in wind turbines are a common use of inductive slip rings. As shown, there are a variety of common slip ring technologies, each with a particular set of performance tradeoffs (Table 1).

Three types of slip rings are commonly used in wind turbines.

- Hub slip rings, as noted above, are usually inductive designs used in large utility-grade turbines.

- Yaw slip rings enable the turbine head on small privately owned turbines to rotate as needed by the wind direction. These are often a type of contact slip ring.

- Generator slip rings are used to carry power in utility-grade turbines.

Robots and slip rings

The slip rings used in multi-axis robots are more varied and can include over 200 circuits in complex designs. In addition, slip rings in industrial robots can be used to link coolant or other fluids between the fixed and rotating parts of the machine.

Hydraulic or pneumatic slip rings are often referred to as rotary unions. In addition to transmitting electric signals and power, these slip rings support the flow of coolant, gases, water, or steam. Some designs include pressure regulation or sensors to monitor environmental parameters and the operating condition of the slip ring. Large hydraulic slip rings are also commonly used in heavy construction equipment like excavators.

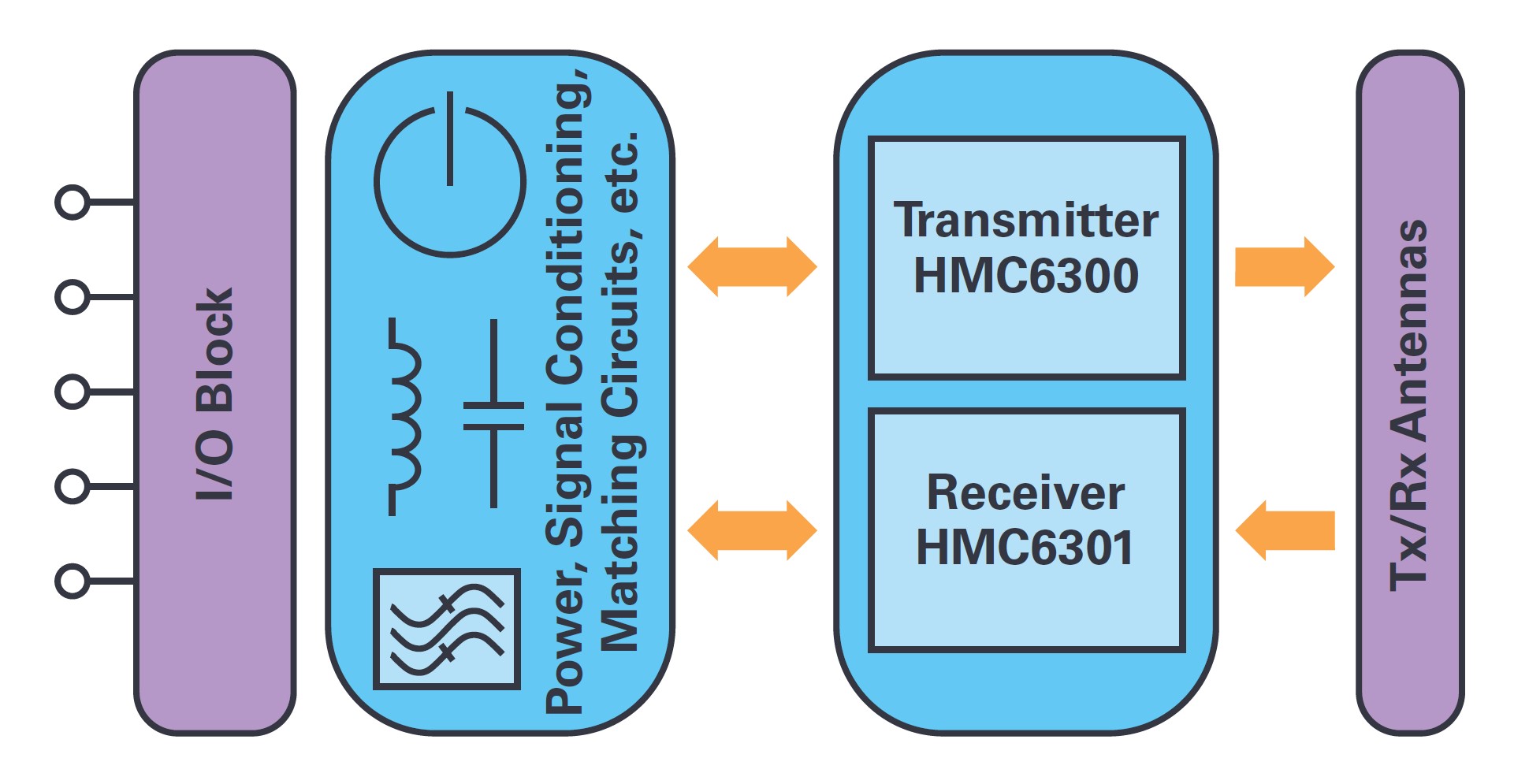

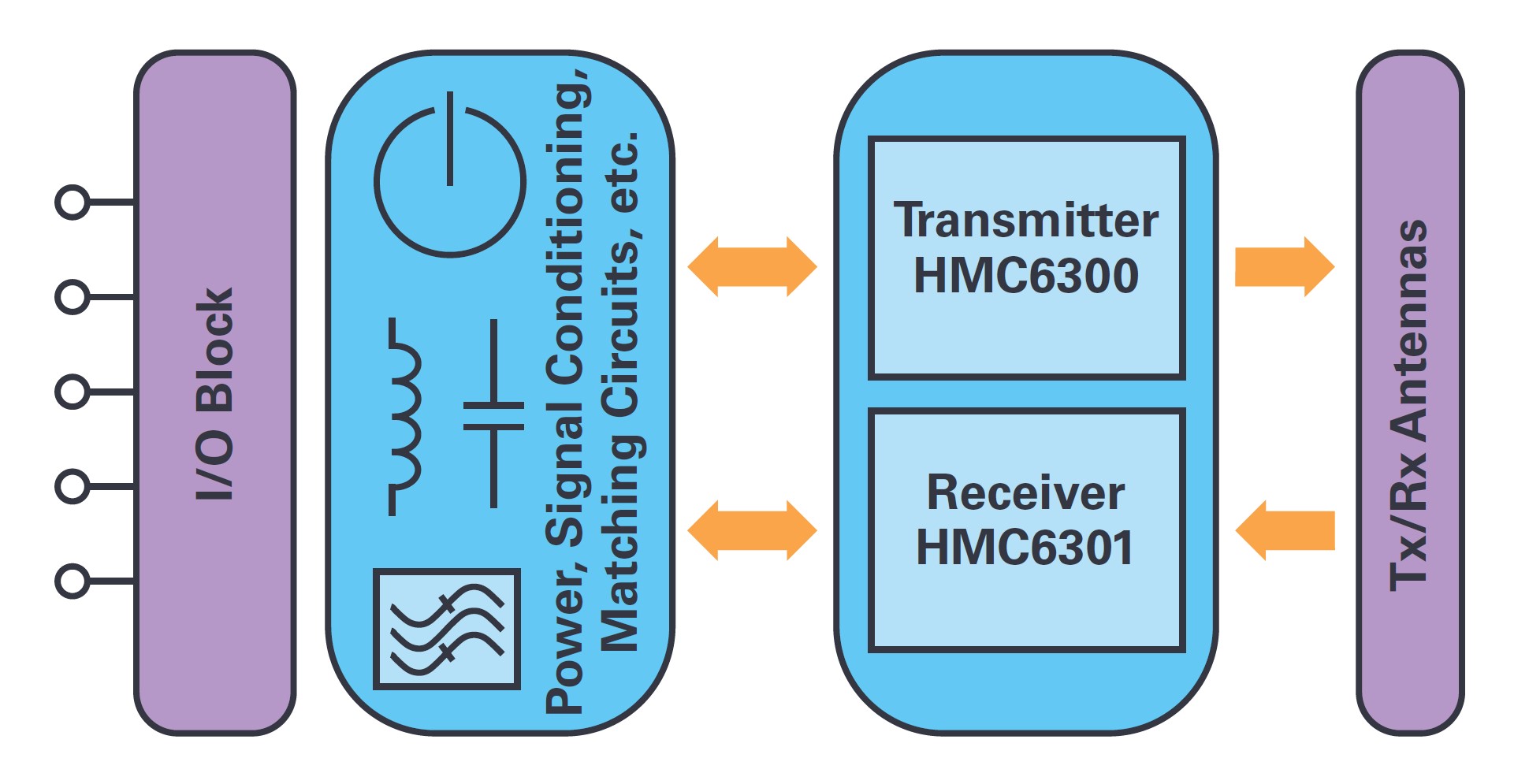

60 GHz wireless data slip ring

A millimeter wave data interface slip ring has been suggested using frequencies from 57 to 64 GHz for industrial applications. The silicon-germanium (SiGe) transceiver was developed for small-cell backhaul systems, but can also support industrial slip ring designs (Figure 3). Using an integrated synthesizer, the SiGe chipset can be tuned in discrete frequency steps of 250, 500, or 540 MHz from 57 to 64 GHz. An external signal can also be used to control the modulation, coherency, and phase noise needs of specific applications.

The transceiver includes support for modulation schemes like on-off keying (OOK), quadrature amplitude modulation (QAM), frequency shift keying (FSK), and minimum shift keying (MSK). It has a maximum output power of 15 dBm and a maximum modulation bandwidth of 1.8 GHz and can be monitored using an integrated detector. The chipset features adjustable low-pass and high-pass baseband filters, a low noise figure, and flexible digital or analog IF/RF gain control.

The receiver signal chain includes an integrated amplitude modulation (AM) detector that simplifies the demodulation of signals like OOK that use amplitude modulation. While the transceiver supports several modulation schemes, OOK is especially suited for control applications like slip rings since it can be implemented without high-speed data converters, which can add to cost and power consumption. In addition, OOK does not require complicated modulation and demodulation stages and can support the low latency needed for real-time industrial control applications.

Summary

Slip rings are important components in various industrial, green energy, and medical applications. Many contact and contactless slip ring technologies include mercury wetted, wireless, inductive, capacitive, and FORJ. In addition to transmitting electric data and power in rotating machines, slip rings send gases and liquids between the rotating sections.

References

60 GHz Wireless Data Interconnect for Slip Ring Applications, Analog Devices